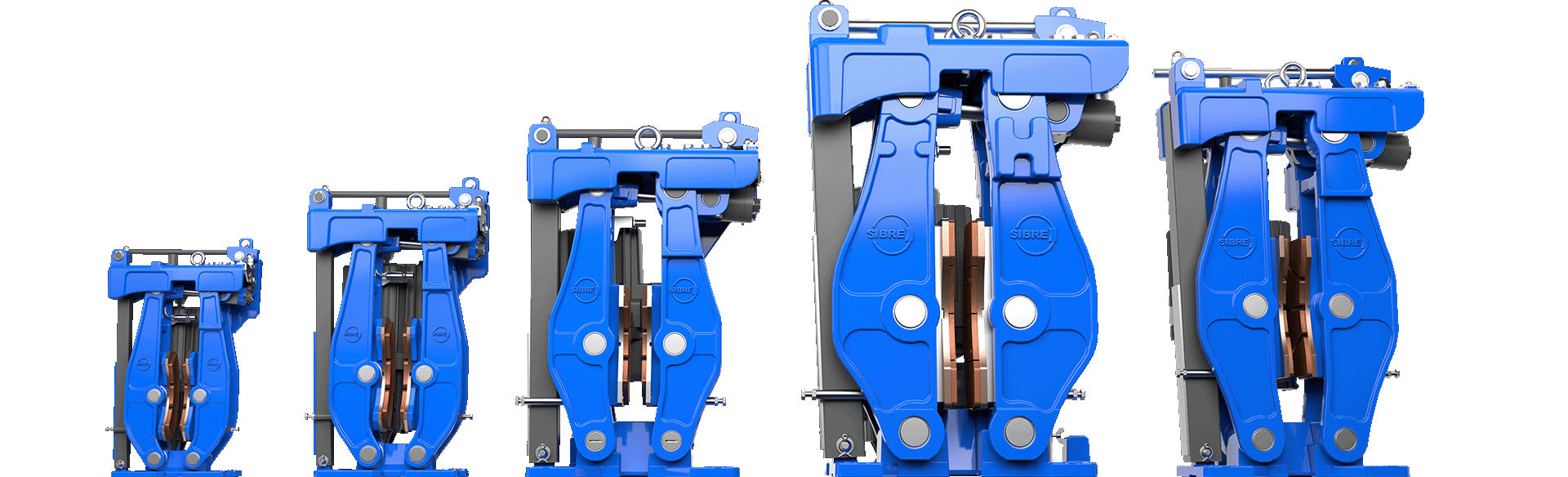

SIBRE HEROES

USB 5

Fail-safe disc brakes

USB 5

datasheet

USB 5 represents the new generation of SIBRE “Maintenance Free” Fail-safe Disc Brakes.

Combining the benefits of both spring and weight applied braking, the USB range is specifically designed to meet the demands of crane-lifting and material handling applications.

Applications

- Primarily used as both Dynamic or Holding brakes for High Speed shaft applications, but also suitable for Low speed applications.

- Ideal as High Speed brakes for Main hoist and Boom Hoists in Container Cranes and Ship loaders, as well as for Conveyor Drives, Bucket Wheel Excavators, Stackers and Reclaimers.

Enhanced design optimizations and several new features offer even more efficient and reliable braking solutions over a wide range of applications.

- Standardized functional principle across 5 sizes, for all crane applications (gantry, boom, slewing, hoist)

- More stable friction coefficient and brake torque

- Simplified alignment of the brake system

- Reduced noise emission

- Upgraded manual release system

- Enhanced corrosion protection

- Robust design with all bearings and pivot points fitted with Teflon coated, white metal bushes

- Rust and acid resistant stainless steel pins

- Braking torque independent of direction of disc rotation

- Graduated torque scale for easy adjustments

- Replaceable, asbestos free, sintered brake linings for high circumferential speed up to 85 m/sec. and max. disc temperature of up to 850°C

- Automatic lining wear compensation

- The SIBRE-synchronisation linkage guarantees equal and synchronous movement of brake arms, ensuring equal lining clearance without any manual adjustment of air-gap.

The types

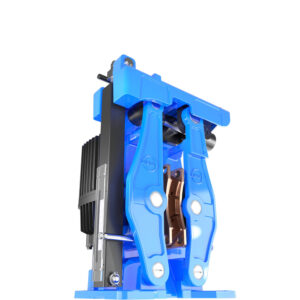

USB 5 II

Braking torque:

1,300 – 9,800 Nm

Peak height:

280 mm

Weight:

175 kg

1,300 – 9,800 Nm

Peak height:

280 mm

Weight:

175 kg